The computational expense of the ICP algorithm depends mainly on

the number of points. In a brute force implementation the point

pairing is in ![]() . Data reduction reduces the time required

for matching. Several approaches have been presented for

subsampling the data, including randomized sampling, uniform

sampling, normal-space sampling and covariance sampling

[20,12]. Randomized sampling selects points

at random, uniform sampling draws samples equally distributed

samples from the input point cloud. Normal space sampling, as

proposed by Rusinkiewicz and Levoy, aims at constraining

translational sliding of input meshes, generated from the point

cloud [20]. Their algorithm tries to ensure that the

normals of the selected points uniformly populate the sphere of

directions. Covariance sampling as proposed by Levoy et al. and

extends the nomal space approach. They identify whether a pair of

meshes will be unstable in the ICP algorithms by estimating a

covariance matrix from a sparse uniform sampling of the input

[12].

. Data reduction reduces the time required

for matching. Several approaches have been presented for

subsampling the data, including randomized sampling, uniform

sampling, normal-space sampling and covariance sampling

[20,12]. Randomized sampling selects points

at random, uniform sampling draws samples equally distributed

samples from the input point cloud. Normal space sampling, as

proposed by Rusinkiewicz and Levoy, aims at constraining

translational sliding of input meshes, generated from the point

cloud [20]. Their algorithm tries to ensure that the

normals of the selected points uniformly populate the sphere of

directions. Covariance sampling as proposed by Levoy et al. and

extends the nomal space approach. They identify whether a pair of

meshes will be unstable in the ICP algorithms by estimating a

covariance matrix from a sparse uniform sampling of the input

[12].

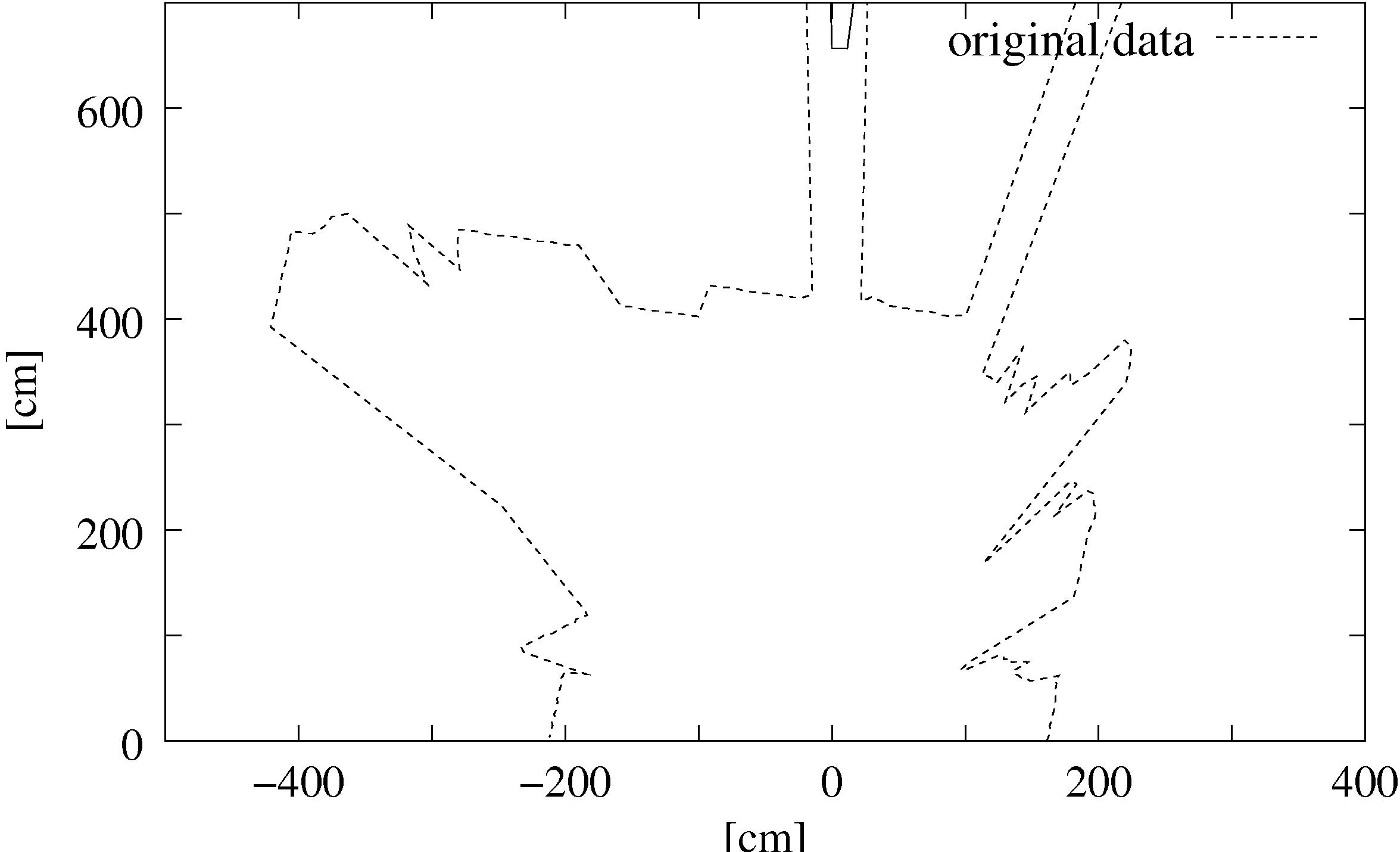

The data reduction proposed here considers the procedure of the scanning process, i.e., the spherical and continuous measurment of the laser. Scanning is noisy and small errors may occur. Two kinds of errors mainly occur: Gaussian noise and so called salt and pepper noise. The latter one occurs for example at edges, where the laser beam of the scanner hits two surfaces, resulting in a mean and erroneous data value. Furthermore reflections lead to suspicious data. Without filtering, only a few outliers lead to multiple wrong point pairs during the matching phase and results in an incorrect 3D scan alignment.

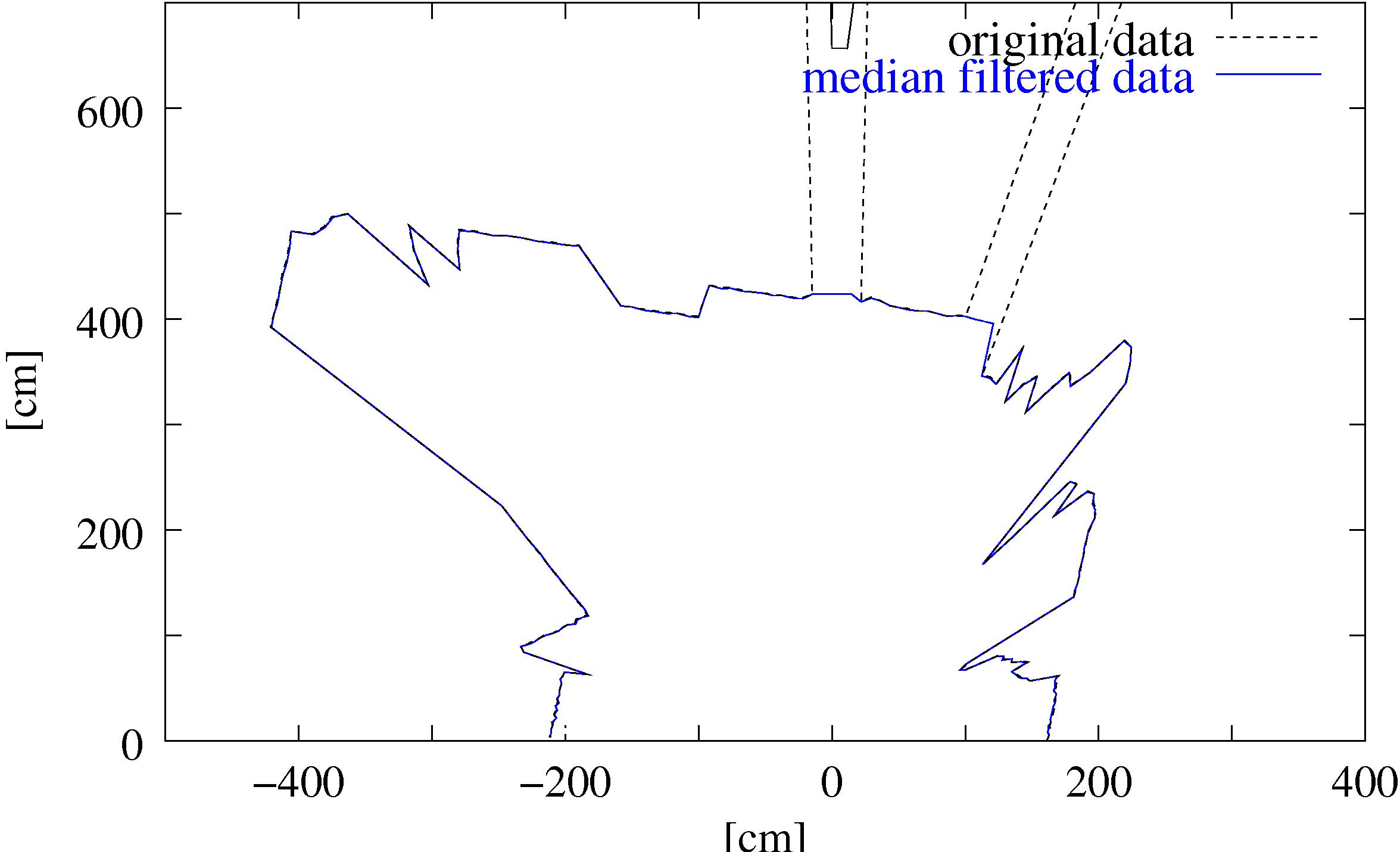

We propose a fast filtering method to reduce and smooth the data

for the ICP algorithm. The filter is applied to each 2D scan

slice, containing 361 data points. It is a combination of a

median and a reduction filter. The median filter removes the

outliers (Fig. 3) by replacing a data point with the

median value of the ![]() surrounding points (here:

surrounding points (here: ![]() ). The

neighbor points are determined according to their number within

the 2D scan, since the laser scanner provides the data sorted in

a counter-clockwise direction. The median value is calculated

with regards to the Euclidian distance of the data points to the

point of origin. In order to remove salt and pepper noise but

leave the remaining data untouched, the filtering algorithm

replaces a data point with the corresponding median value if and

only if the difference (Euclidian distance) between both is

larger than a fixed threshold (here: threshold = 200 cm).

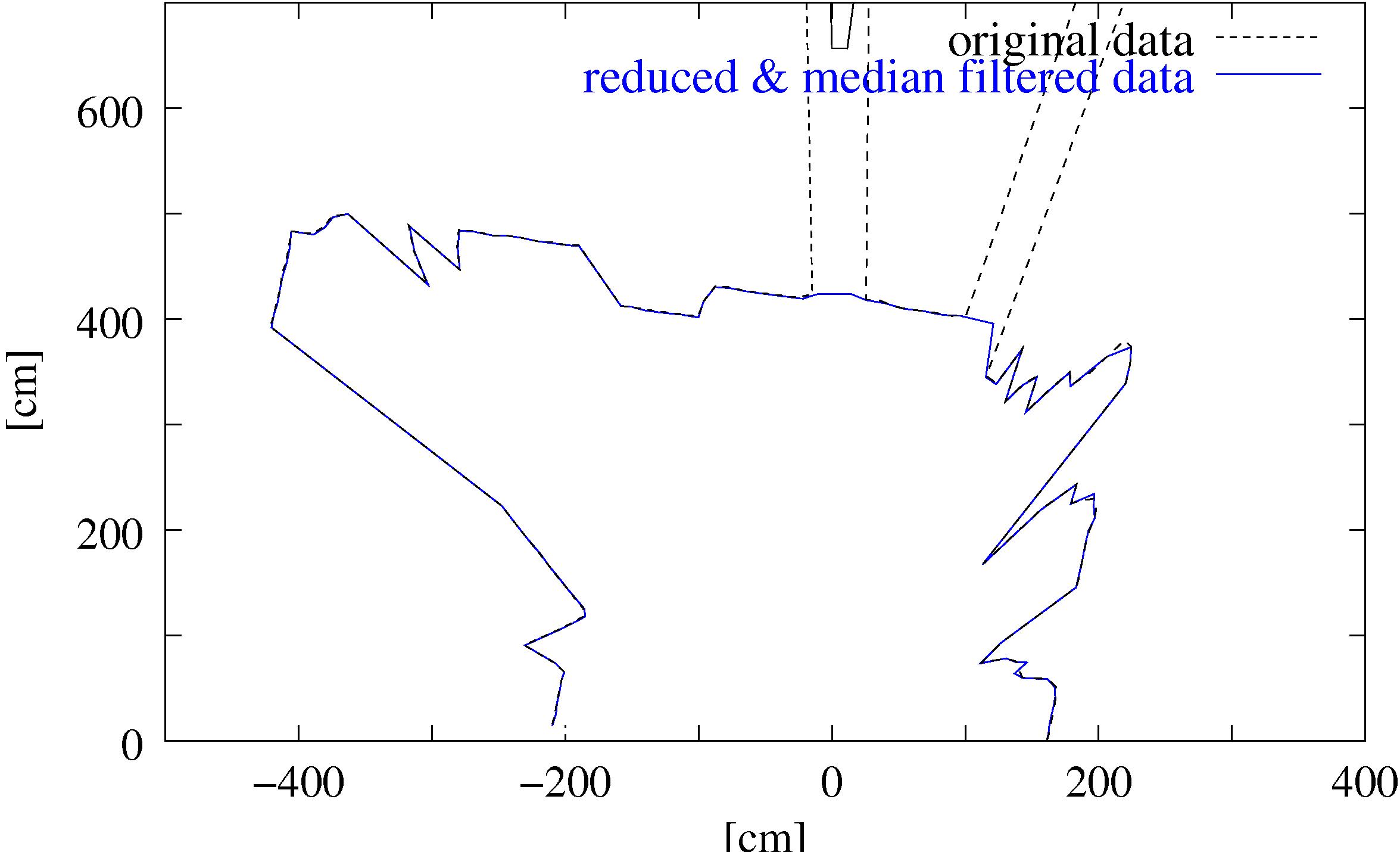

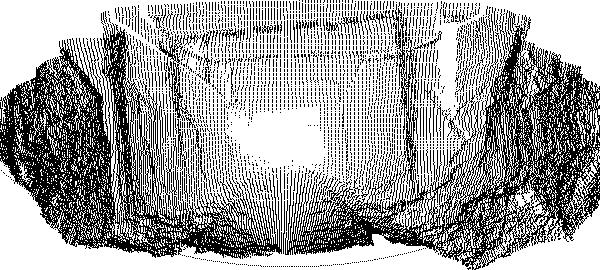

The data reduction works as follows: The scanner emits the laser

beams in a spherical way, such that the data points close to the

source are more dense. Multiple data points located close

together are joined into one point. This reduction lowers the

Gaussian noise. The number of these so called reduced

points is in the mine application one order of magnitude smaller

than the original one (Fig. 3). Finally the data

points of a slice have a minimal distance of 10 cm and

approximate the surface. The clue of the algorithm is that it is

nearly impossible to detect differences between the median

filtered and the reduced data (Fig. 3). The reduction

fulfills the sampling criterions stated by Boulanger et

al. [6], i.e., sampling the range images, such

that the surface curvature is maintained.

). The

neighbor points are determined according to their number within

the 2D scan, since the laser scanner provides the data sorted in

a counter-clockwise direction. The median value is calculated

with regards to the Euclidian distance of the data points to the

point of origin. In order to remove salt and pepper noise but

leave the remaining data untouched, the filtering algorithm

replaces a data point with the corresponding median value if and

only if the difference (Euclidian distance) between both is

larger than a fixed threshold (here: threshold = 200 cm).

The data reduction works as follows: The scanner emits the laser

beams in a spherical way, such that the data points close to the

source are more dense. Multiple data points located close

together are joined into one point. This reduction lowers the

Gaussian noise. The number of these so called reduced

points is in the mine application one order of magnitude smaller

than the original one (Fig. 3). Finally the data

points of a slice have a minimal distance of 10 cm and

approximate the surface. The clue of the algorithm is that it is

nearly impossible to detect differences between the median

filtered and the reduced data (Fig. 3). The reduction

fulfills the sampling criterions stated by Boulanger et

al. [6], i.e., sampling the range images, such

that the surface curvature is maintained.

The data for the scan matching is collected from every third scan slice. This fast vertical reduction yields a good surface description. Data reduction and filtering are online algorithms and run in parallel to the 3D scanning.

|

|